Mpact® Downhole Motors is a leading supplier of premium drilling motors. Our lower ends are designed and manufactured in house at our Conroe, Texas headquarters, and currently have millions of feet drilled with over 99% success rate.

Mpact® dedicates its capabilities and places its reputation on:

- Proprietary field-proven designs for maximum performance

- Extensive experience with a variety of drilling scenarios

- Professional and responsive customer service

- Strict quality standards and premium materials for reliability

- Superior performance within difficult drilling applications

- Engineering and product development expertise providing timely innovative technological solutions

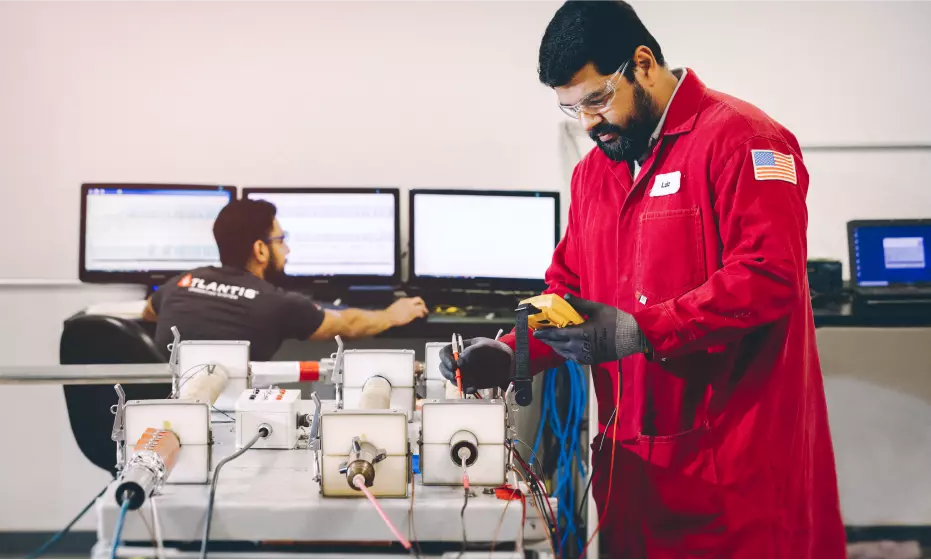

At Mpower™, we design, engineer, source, and manufacture the key components of our MWD Systems in-house. This gives us full control over product development, R&M, and QA/QC, making it one of the most reliable tools in the market.

The home of our innovations is our Katy Technology Center (KTC) – a dedicated engineering and product development center with over 100 years of downhole MWD experience.

Our in-house engineered, designed, and developed products include:

Mercury™ Pulser (MP)

Mercury™ Directional Module (MD)

Atlantis™ Dual Transducer Decoder (DTD)

Atlantis™ Data Compression

Drilling Dynamics Measurements

Our latest elite MWD tools include:

Mercury™ HT – developed for high temperature operation

Mercury™ RT – providing real-time RSS communication

Mercury™ CB – Collar based tool coming soon

Mercury™ Pulse MWD System

- Revamped in 2022

- Proprietary motor control algorithm for superior reliability

- Condition-based maintenance (CBM)

Atlantis™ Data Compression

- High-Definition Logging Capabilities

- Longer Battery Life

- Simplified Field Operations

- Increased Tool Reliability

- Faster Survey Measurements

- 5x Gamma Depth Resolution

- Superior Measurement Depth Tie-in

- High Precision Survey (CINC/CAZM)

- Patent Pending

Atlantis™ Dual Transducer Decoder (DTD)

- Dual pressure transductor surface decoding system

- Proprietary signal processing algorithm

- Fully integrated with PTEN+

- Organic support for remote operation

- Patent pending

Mercury™ RT RSS Communications

- Real-time communication with SLB BabelFish and Orbit RSS

- Proprietary D&I (MDG) and Pulser (MP) platform

- Support all hole sizes

Mercury™ MD Direction Module

- Industry leading next-generation directional module

- Proprietary algorithm to provide superior D&I measurements

- Approved high-reliability

- Drilling Dynamic Measurements (DDM) capabilities

Mercury™ MP Pulsar (MP)

- Proprietary motor control algorithm for superior reliability

- Condition-based maintenance (CBM)

Mercury™ HT

- Industry leading qualification standard

- Fully EQ at 175C

- Target 190C qualification in Q3 2024

Mercury™ CB – Collar based tool coming soon

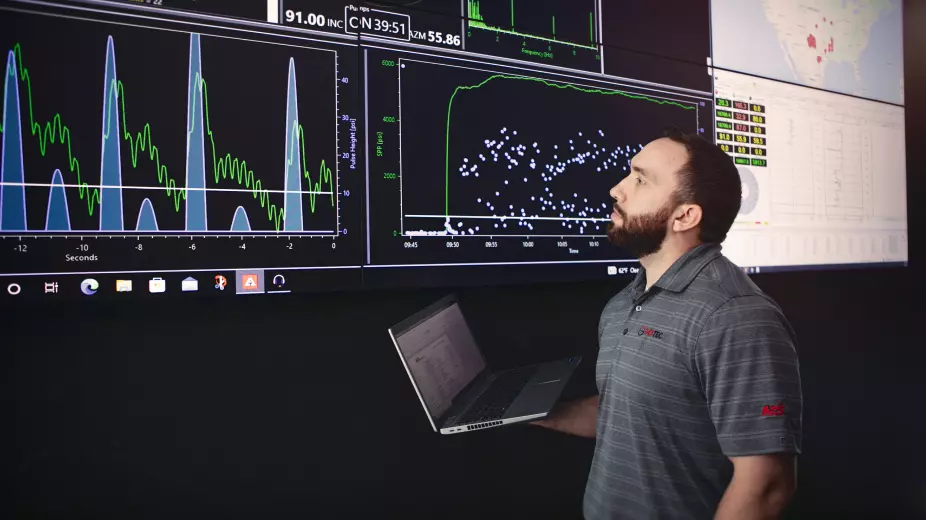

Functioning as the center of MS Directional's MWD and Directional operations, all information flows through GOTEC® (Global Operations Technical Evaluation Center) to ensure success for each of our client partners. At our command center, headquartered in Houston, TX, GOTEC® is outfitted with multiple state-of-the-art workstations designed for the demands of MS Directional's 24/7 live monitoring and support operations.

- Advanced pre- and post-run QA/QC to ensure accurate MWD operations

- Post-run tracking of MWD component hours for preventative maintenance

- End of Well data QA/QC; Prepared and certified for final reporting to customer and regulatory agencies

- Data acquisition for Mpower®/Mpact™ incident analysis

- DR/VR Database system tracks all incidents, both internal and customer-facing, to generate and track current MWD reliability data

- Remote MWD operations and troubleshooting

We have a team of experienced, extensively trained well planners that work directly with our customers and coordinators to produce the most accurate well plans possible. While accuracy is vital to drilling success, we also stress perpetual safety and efficiency in our plans so that our customers see optimal value and returns on their projects.

We use Landmark COMPASS™ and AutoCAD®—both industry standard packages—to create customized well plans. Not only does this allow us an opportunity to maximize potential, but it also affords our customers an opportunity to visualize the approach and provide feedback before any drilling begins. We provide customers with well plan drawings, traveling cylinder plots, and well plots so that informed collaboration between all parties can occur.

We provide services including well design; AC monitoring and collision avoidance; identification of lease and hard line crossings; daily well updates; and end-of-well reporting. We have experience with multi-lateral, extended reach, turnazontal, s-well, build, and hold wells.

All of our field personnel are experienced in multi-well pad drilling, monitoring anti-collision at the field level, and providing expert opinions to improve results in your directional drilling application. We are team-oriented and strive to work as one with our customers.