Many of Warrior's employees have been in the industry for 30+ years, and have designed, developed and manufactured drilling rig components. Learn more about our designers, shop, and field technicians with extensive oilfield and tubular handling experience.

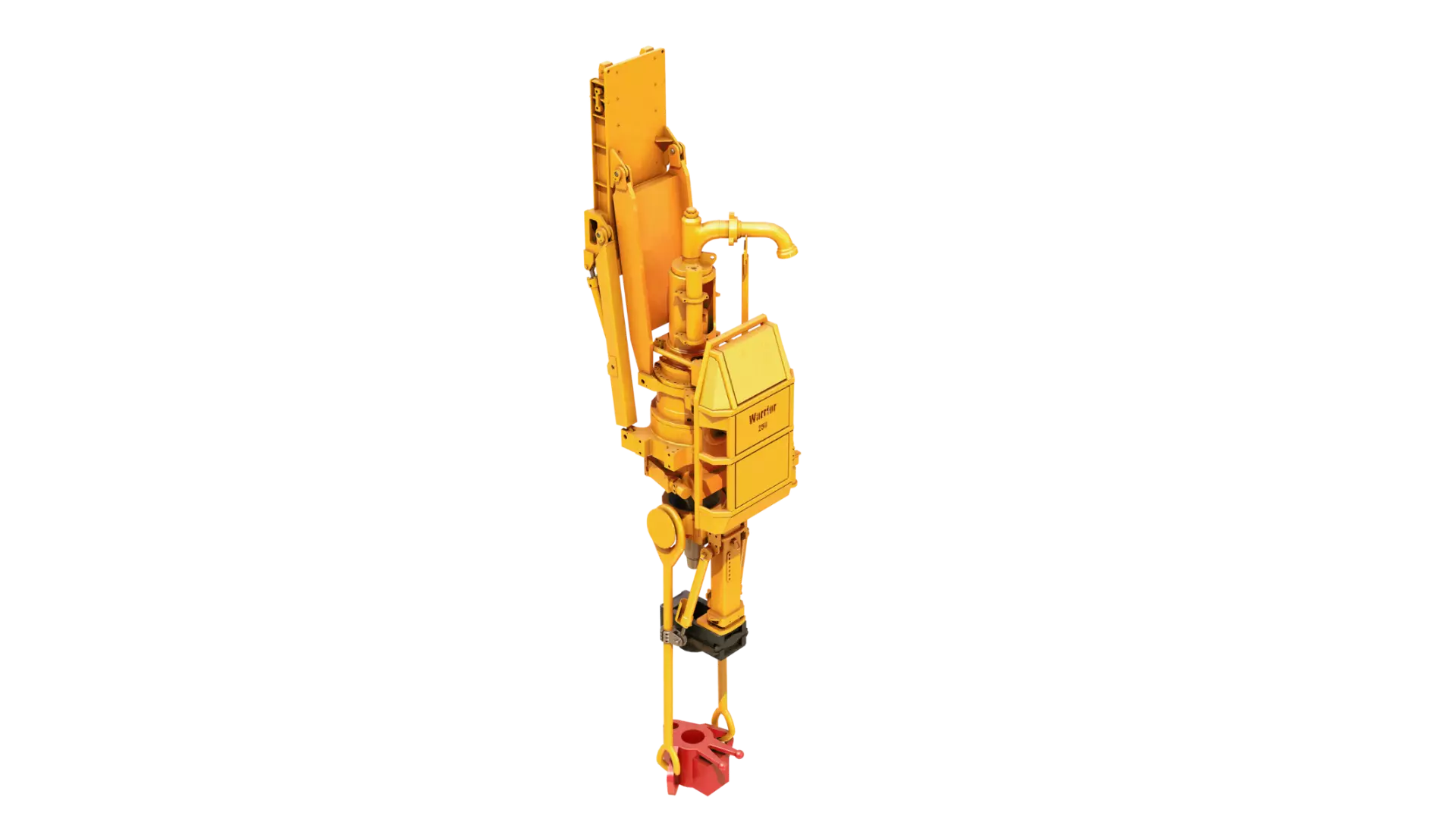

Warrior engineers, designs and manufacture hydraulic top drives ranging form 110 to 350 tons.

Featured Design Benefits:

- Easy to handle, light and quick to rig-up guide rail mounted in the mast.

- PLC controls with interlocks and diagnostic readouts at the driller's console and hydraulic power unit.

- Direct drive motor; Warrior's hydraulic top drives use a through-bore direct drive motor (there are no mechanical gears between the top drive motor and quill). This eliminates a transmission within the top drive which adds weight and is generally a higher maintenance item. Also, with a direct drive, the torque of the motor is applied directly to the quill (no power losses as in gear drives). This provides for high torque capabilities in a more compact package.

- Floating quill; internal axial movement of the quill provides for soft stabbing and protection of the top drive during rough drilling (replaces the need for a cushion shock sub).

- Advanced hydraulic system for motor protection on the top drive including a fail-safe manifold to prevent motor backspin from downhole torque (controlled de-torque of the drill string) and an accumulator system to protect the motor during rough drilling conditions.

- Hydraulic-actuated lower well control valve.

- Independent hydraulic drive system with diesel or AC motor drive. The system is compact and can be a standalone unit or packaged in a building with other equipment.

- 360 degree pipe handling system is available on certain models.

- API 8C Licensed

| 110H70 | 250H14 | 250H14HR | 3527H14HR | |

| Hoisting Capacity | ||||

| Static (Elevator Load Path) | 110 tons | 250 tons | 250 tons | 350 tons |

| Static (Quill Load Path) | 110 tons | 250 tons | 250 tons | 275 tons |

| Dynamic (Bearing) | 110 tons | 250 tons | 250 tons | 275 tons |

| Breakout Torque | 16,500 ft-lb | 32,000 ft-lb | 32,000 ft-lb | 35,000 ft-lb |

| Continuous Torque Rating | 13,500 ft-lb | 26,000 ft-lb | 26,000 ft-lb | 28,000 ft-lb |

| Layout Drawing | 110H70 Bail with Guide Rail | 250H14 | 250H14HR | 3527H14HR |

| 110H70 with Split Traveling Blocks |

Warrior manufactures a wide assortment of traveling blocks suitable for many rig applications. With sizes that range from 110-ton to 650-ton. Warrior can provide a reliable, compact innovative traveling block to suit your needs.

Highlights and Features:

- API 8C Licensed

- E-Z-Becket™ Retractable Beam Connector eliminates the inefficiencies and hazards of the traditional pinned becket

- Compatible with standard API contact profiles

- Individual lubrication for each sheave

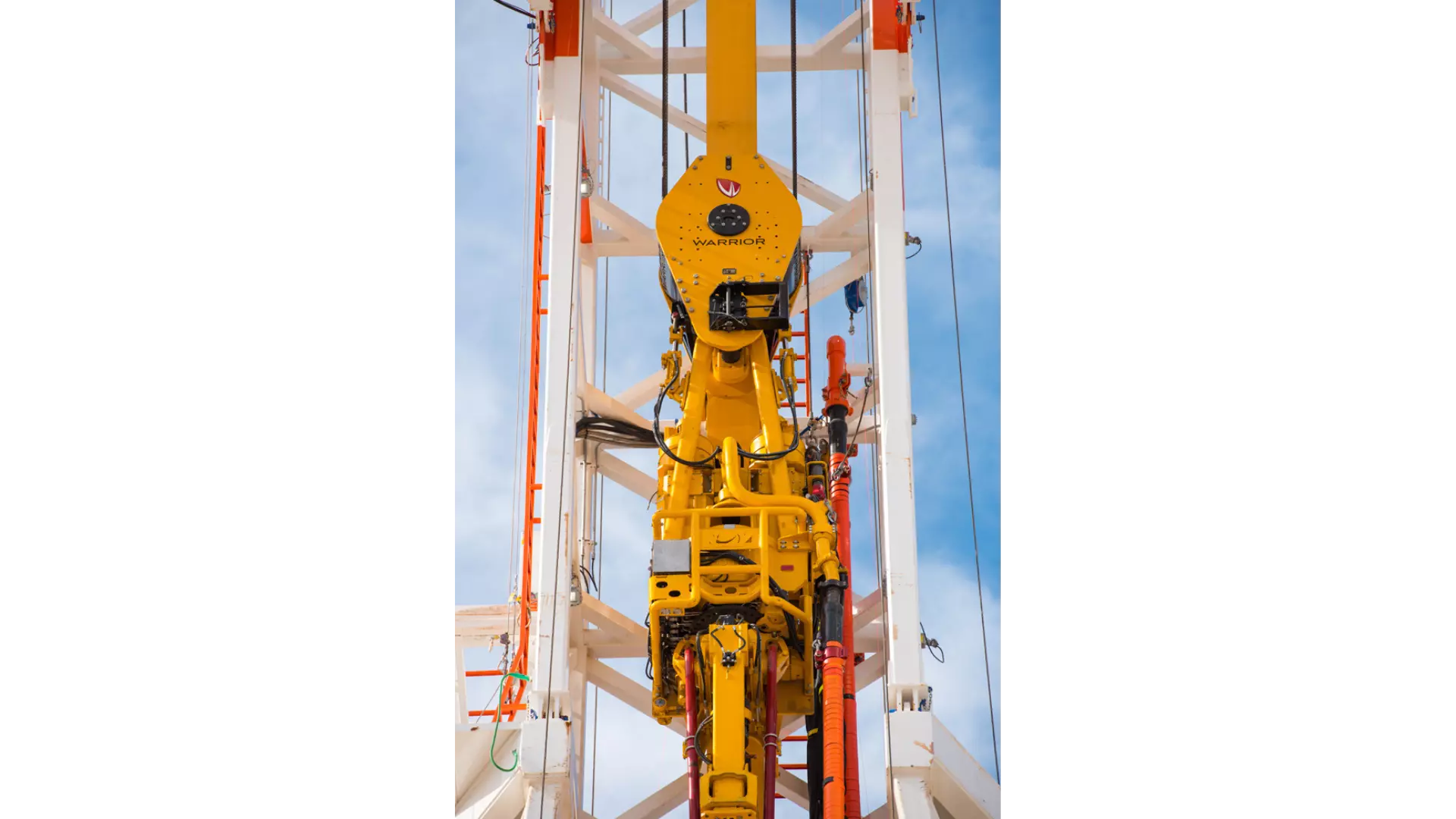

Split Blocks

Warrior can design and manufacture top drives to meet specific rig requirements. Split block systems maximize mast headroom and allow Warrior top drives to be installed into smaller rigs. Split blocks minimize working length and provide clear vertical access through the top drive for wireline operations.

Warrior specializes in the service, rebuild and remanufacture of our products with experienced service and support technicians who have been involved in all aspects of domestic and international field support including installations, commissioning, training, repair and maintenance.

The field service group has a dedicated full-time service coordinator, including 24/7 engineering support while maintaining a large inventory of replacement parts to support equipment in the field.

To provide the highest level of support in foreign countries, Warrior employs and trains in country representative(s) and stocks parts locally.

Warrior offers comprehensive training courses designed to introduce participants to our Top Drive systems. Warrior offers a variety of top drive courses covering all aspects of top drive systems including hydraulic, mechanical and electrical systems, rig-up and rig-down procedures, general operations and routine maintenance. Each course includes a functional description of Top Drive system components as well as an overview of troubleshooting methods.

Warrior can also provide classroom and on-site training to drilling personnel and specialized trouble-shooting and repair training for mechanics and electricians.

Phone: 817-220-0144

Service: service@warriorrig.com

Parts: parts@warriorrig.com

Training: info@warriorrig.com